E-Learning for Lab Classes

After the SARS outbreak in the year 2004, the Ministry of Education (MOE) implemented a new education scheme called E-learning for the students. During the E-learning week, students are not required to come to school but they are given homework. Their lecturers have put up lesson of their respective module in the school website and through there, students are required to learn on their own and get their work done. To enable a more interesting way of learning, we introduce E-learning for lab Classes whereby students can do Laboratory experiment at home.

The students examined the possibility of using data acquisition (EMANT300) to link existing lab equipment to PCs and allow users to get remote access to Lab Equipment. This would allow the experiment to be remotely controlled using appropriate software. They designed the programme using Microsoft Visual C# and internet-enabled the equipment using Remote Assistance.

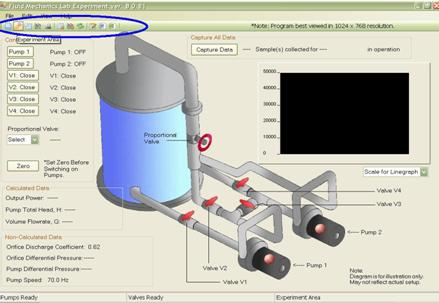

Overview of the Equipment

The equipment comprises of two identical centrifugal pumps driven by electric motors which are mounted on a support plinth together with a clear acrylic reservoir and associated interconnecting pipework for continuous circulation. Configurations of either series, parallel or single pump operation can be set using the appropriate valves (V1, V2, V3, and V4). Clean water is used as the operating fluid and a drain valve at the base of the reservoir allows the water to be drained after use. The flow of water through the centrifugal pumps is regulated by a flow control valve installed in the discharge pipework of the unit. Adjustment of this valve allows the head/flow produced by the pumps, either separately of combined, to be varied.

Operation of the Equipment

Series Pumps Operation

Operating pumps installed in series method may be used if the desired effect is an increase of the head at the delivery side. To have the pumps in series, valve 1 and 3 opened. Valve 2 and 4 closed.

Parallel Pumps Operation

Operating pumps installed in parallel method is used for an increase in the original flow rate of up till some 50% and 75%. To have the pumps operate in parallel, valve 1, 2 and 4 are opened. Only valve 3 is closed

Pressure Sensor

Two pressure sensors were used - one to calculate the pump head and and the second to measure the orifice differential pressure.

Actuator for Pumps

The actuator for pumps swtiches power to the pump motor 1 and pump motor 2. This actuator can only do the on/off of the pump motors. It cannot adjust the speed of the motor. The actuator comprises relays which switches on/off the pumps depending on the digital output of the EMANT300.

Actuator for Solenoid Valves

The actuator for the solenoid valves requires an 12V 2A power adaptor which provides the power to drive the valves. The board uses the ULN2003 (7channel Darlington Sink Driver IC) to drive the current required by the solenoid valves. Driving the valves directly from the EMANT300 outputs will damage the EMANT300.

For the full report, please email Mr Selva Raj , their project supervisor at Singapore Polytechnic.

Note: The project won the Gold award which is given to the top 5% of the final year projects.